CONTINUOUS SYSTEMS FOR SMOKING, COOKING AND COOLING

SET NEW STANDARDS IN TERMS OF QUALITY AND EFFICIENCY

STATE-OF-THE-ART CONTROL TECHNOLOGY

CLEARLY ARRANGED OPERATION ∙ HIGH RESOLUTION ∙ ALL DATA AT A GLANCE

Due to individual requirements different control systems are available – large colour touch-screen LCD controls or 10.4-inch touch-screen industrial panels for free programmable functions.

Our control technology has a comfortable quality management with production control, so that no separate device is required. The software architecture is tailor-made for everyday use and characterized by numerous features such as recording interval, screen layout sequence, alarm limit values for all recording systems, graphical data output, numeric and/or graphic print form, etc.

All operator functions are itemized into menu-driven groups in order to guarantee a simple and logical handling.

Technical data

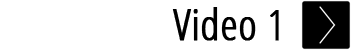

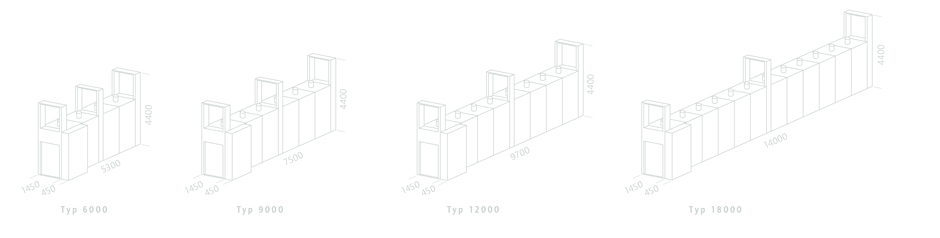

| Heating capacity kW | Cooling capacity kW | Consumption kg/h | Smoke trolleys | ||||||

| Type | Engine power (kW) | Electricity | Oil *) | Gas *) | Glycol, freon, ammonia | Low pressure steam 0.3-0.5 bar | High pressure steam 6-8 bar | Quantity | B/T/H |

| 6000 | 15 | 57 | 54 | 54 | 30 | 100 | 110 | 2 + 2 | 100/100/200 |

| 9000 | 21 | 75 | 80 | 80 | 45 | 150 | 165 | 3 + 3 | 100/100/200 |

| 12000 | 27 | 100 | 108 | 108 | 60 | 200 | 220 | 4 + 4 | 100/100/200 |

| 15000 | 34 | 120 | – | – | 75 | 250 | 275 | 5 + 5 | 100/100/200 |

| 18000 | 42 | 150 | 160 | 160 | 90 | 300 | 330 | 6 + 6 | 100/100/200 |